re-useable excavated material

heavy-duty design

maintenance-free bearing assembly

the robust design of the drum bearings provides optimal force absorption

no drain line required

less vibration

less noise

- easy cutting of the rebar

- depth control for hard rock application

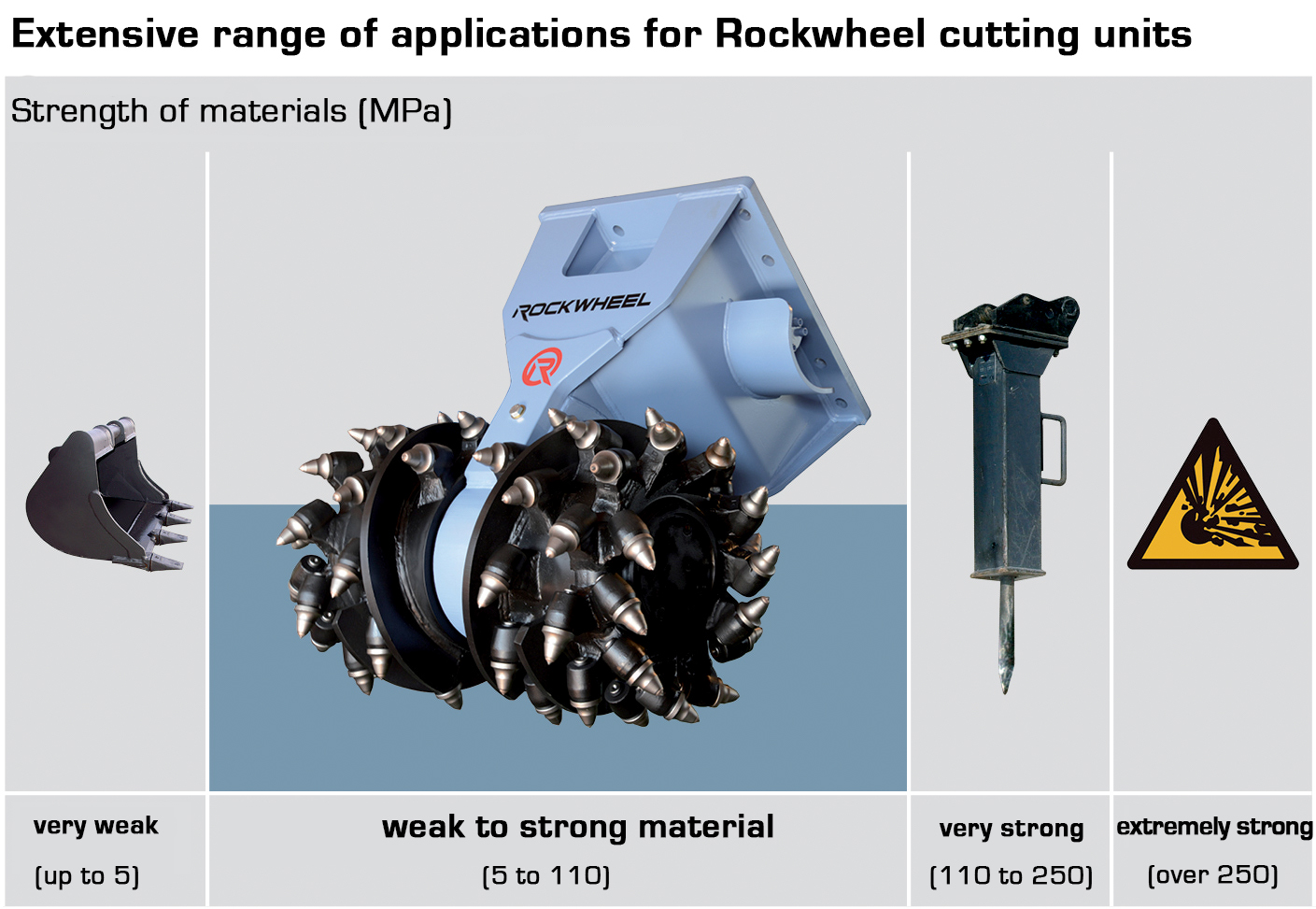

Cutting units are the right choice - if the material is too hard for the bucket, but not so hard that only a hammer or blasting would cut it.

One-step crushing of concrete rebar, due to the Rockwheel power.

A hammer does not crush concrete with rebar. Rockwheel can do it all in one step - no additional tools are needed.

Rockwheel are designed for the toughest applications. The massive Hardox helix section and heavy duty picks made of hard metal are virtually unbreakable.

The Rockwheel is more robust than other heavy-duty design on the market.

Rockwheels can be used in noise-sensitive areas like cities or residential areas. The units work almost silently. The main noise comes from the excavator and from the crushed material.

Rockwheels also generate very little vibration in surrounding areas and buildings.

Robert Piasecki & Klaus Volkert

CEOs of Rokla GmbH

"The foundations of a wall were in the way of our new paving in the courtyard. Thanks to the rockwheel they were demolished within a few minutes, with very little noise. Actually all we heard was the excavator. Perfect because we didn’t want to disturb our neighbours"

"With very little vibration - that’s how the Rockwheel cutting units work. This is so much better than demolition with a hammer. Our excavator operators in particular are very pleased! The vibration-free work with rockwheels makes their life so much easier!"

"We often use Rockwheels. Because of their flexible use they are the perfect solution for me as a builder. They are just the thing for demolition work- within a few minutes we broke down an entire garage into very small bits, so the removal was no problem either"

Rokla GmbH

Hauptstr. 197

74595 Langenburg

Phone: +49 (0) 7905 941 99 0

Fax: +49 (0) 7905 941 99 0

E-Mail: info@rockwheel.com

CEOs: Robert Piasecki, Klaus Volkert

Commercial register: Ulm HRB 729176

UID: DE815425667

Responsible for content: Sabine Piasecki

Design and Development:

iomicron GmbH & Co.KG

Bahnhofstraße 6

91617 Oberdachstetten

Phone: 0 98 45 / 9 85 95 95

Website: www.iomicron.de

For suggestions about the design or questions about the content of these web pages, please send us an e-mail.